Banpu NEXT introduced five technology – smart solution trends that modern business and industrial enterprises should embrace and apply to their operations end to end to increase competitiveness, reduce long-term costs and build sustainable growth. Adoption will also pave way for smart business transformation towards Smart Eco 4.0 and Smart Factory models to equip businesses with the readiness to respond to any situation.

Mr. Chanit Suwanparin, Senior Vice President – Customer Experience, Banpu NEXT Co., Ltd., said, “Technology disruption, global warming, COVID-19 and labor shortage have all fast-tracked enterprises’ adoption of technologies and smart solutions to drive operational strengths in multiple dimensions. This coincides with a new report by Kasikorn Research Center that forecasted a growth of 9.4% in Thailand’s smart factory solutions (SFS)*, the technologies and smart solutions that will be keys to ecosystem development towards Smart Eco 4.0 and Smart Factory by providing complete upgrade to production processes and factory management.”

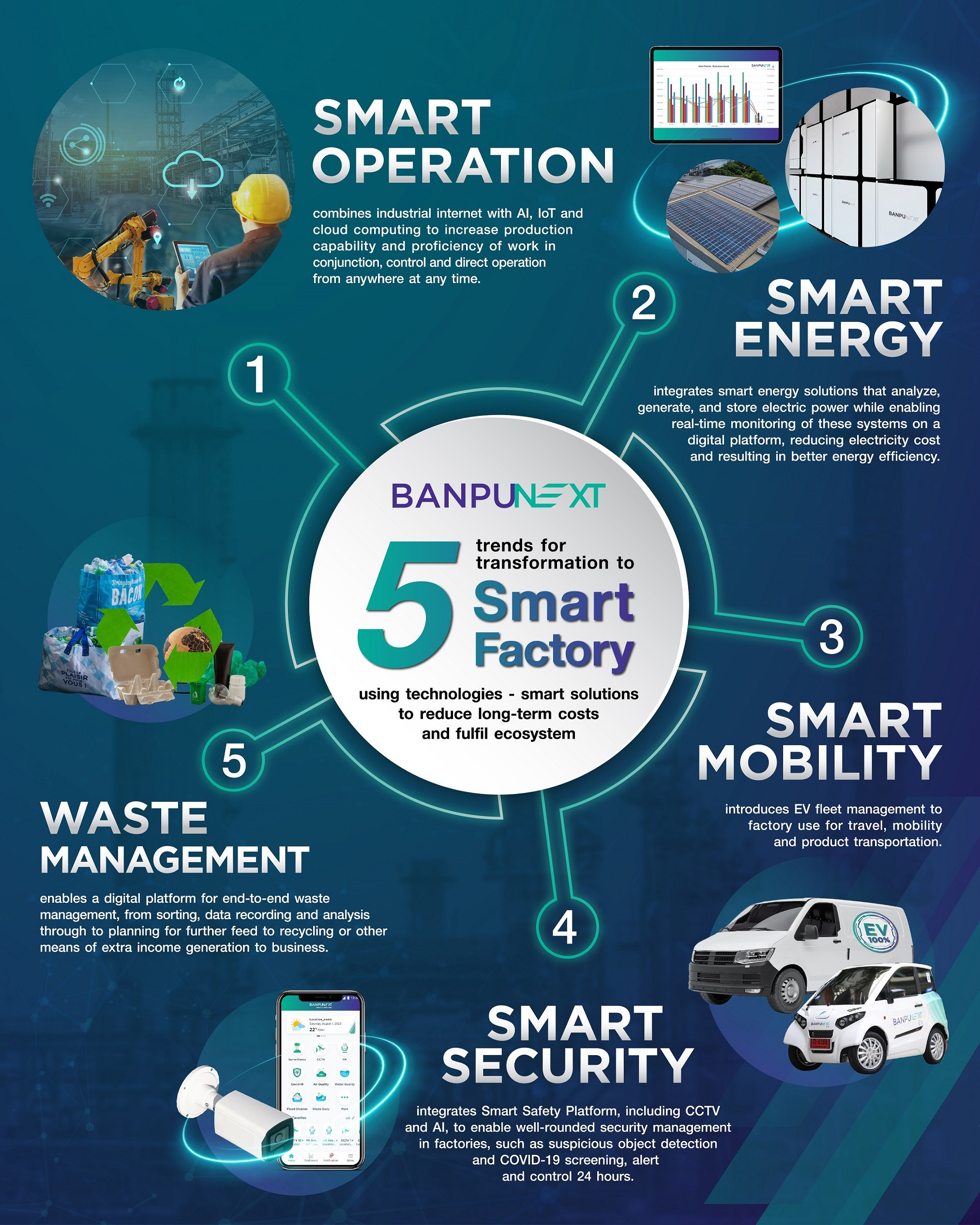

The five example applications of technology and smart solution trends:

- Smart Operation applies industrial internet to increase production capability and efficiency. For example, it combines robots, mechanical arms, automation, and sensors with AI, IoT and cloud computing to establish connection between factory machines, database, and human staff, making it possible to control, direct and communicate with one another to work in conjunction all over the place all the times. Big data can also be used to analyze production process, predict raw material flow, and evaluate machine performance, etc.

- Smart Energy uses technology and digital platform to monitor, evaluate and analyze energy consumption and electrical devices to optimize energy consumption in factories. Integration of smart energy technology also optimize electrical efficiency, reduce CO2 emission, and lower electricity cost significantly, such as by using ‘Solar Power System’ to generate electric power in addition to supply from the grid. Optionally, ‘Energy Storage System’ can be installed to increase stability of electric power and ensure 24 hours of continuous power supply for non-stop production. Moreover, ‘Microgrid’ is another useful solution, being a self-contained system that generates, stores, and supplies electric power all in one. Functioning of all these technologies can be monitored in real time on a digital platform.

- Smart Mobility introduces fleet management and electric vehicles to factory use for general mobility, in-warehouse product mobility and external product transportation, etc. It provides a digital platform complete with application to enable real-time monitoring of vehicles’ travel status and engine performance, plus real-time notifications on any errors.

- Smart Security integrates Smart Safety Platform, including CCTV and AI technologies, to enable well-rounded security management in factories. It can track down suspicious objects and/or persons, detect smoke and perform COVID-19 screening for real-time situation monitoring, alert, and direction.

- Waste Management transform factories’ waste littering into systematic and proper waste management, using a digital platform to enable end-to-end management of the wastes. It sorts waste products and waste materials, for example, and then perform data recording, analysis and planning for further management, such as recycling, recreation and selling to generate extra income to business.

Adopting above trends can bring multidimensional benefits to businesses. They lead to long-term gains from cost-saving on electricity, labor, and other resources. Operational efficiency increases across production volumes, speed, precision, quality, and energy efficiency. In-depth data gained from the systems can be used for business development, which is made possible by improved operation. Besides, workplace safety increases due to better factory accident prevention and lower risk of COVID-19. All-around sustainable operation helps reduce CO2 emission and overuse of energy and resources, resulting in better quality of life. In addition, business value grows due to enhanced business image in alignment with ESG principles, resulting in the capability to upgrade into a prototype Smart Eco 4.0 and Smart Factory operation.

“To prepare for Smart Eco 4.0 and Smart Factory, enterprises should identify their pain points and evaluate their needs, costs, and other factors in order to choose an experienced, full-service smart solution provider that meets their expectations and offers support from an expert team. Banpu NEXT provides an extensive range of smart solutions, including smart data analytics & energy management solution, solar power system, microgrid, fully integrated mobility as a service (MaaS) and e-mobility solution, and smart safety platform. All of them features a digital platform and application that enable real-time monitoring, control, and direction, making them an important piece of the jigsaw puzzle for factory and industrial estate development towards a smarter, more eco-friendly, and more sustainable operation,” Mr. Chanit concluded.

Business entrepreneurs interested in the Smart Energy Solutions for Sustainability and other solutions from Banpu NEXT sign up at https://cutt.ly/BanpuNEXT-SmartFactory or contact call center 02-095-6599.

#BanpuNEXT #SmartEnergySolutionsForSustainability #SmartSolutions

*Source: https://www.kasikornresearch.com/th/analysis/k-social-media/Pages/Smart-Factory-FB-18-10-21.aspx